Come and meet the Harlow-FasTech team at EMO

We will be joining Gerfectec on their Stand K03 at the forthcoming EMO exhibition (Hanover 16th-21st September 2019). EMO is the world’s premier show for the metalworking industry with over 130,000 visitors expected.

Our job shop partnership for 3DMP® services with Gefertec

We are delighted to announce that we have a job shop partnership for 3DMP® services with Gefertec. We can provide cutting edge metal additive 3D printing, using the first such machines in the U.S, at our site in Danville, Virginia.

Faster lead times and reduced costs

Up to ten times faster than conventional manufacturing methods, our wire arc additive manufacturing process, using our GEFERTEC 3DMP® arc405 and GEFERTEC 3DMP® arc605 delivers 3D printing without lasers or powders.

- Ten times faster lead times than traditional manufacturing methods

- Lower material costs as nearly 100% materials utilization

- Broad range of materials available – only limited to available wire stock

- Weld deposition in 5 axes, without printing additional support structures

- Extremely flexible – ideal for one off prototypes

- Easy sourcing, handling and storage of base materials

Our finishing capability

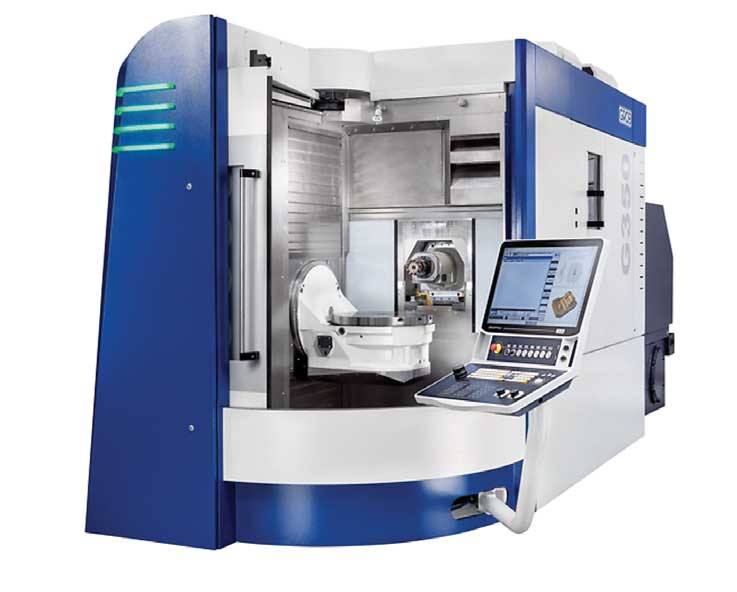

The products that have been “grown” through our 3D capability are then finished using either our Haas UMC 1000 SS Series or our Grob G350 5-axis Universal Machining Centers.

Grow, finish and go. Find out more about our 3D metal printing and milling process

If you are going to EMO, do drop by the Gefertec stand, K03, to meet the Harlow-FasTech team and to find out more about our 3D metal printing capability.